More Information on Terminal Blocks

Interpower terminal blocks are intended specifically for use in making the internal connection between the power cord and the primary circuitry of the equipment. Three-wire terminal blocks provide connection points in single-phase applications with terminals for line, neutral, and ground. Five-wire terminal blocks are used in three-phase applications with terminals for three lines, neutral or common, and ground. Six-wire terminal blocks can be used in either single-phase or three-phase applications. In a single-phase application, the 6-wire terminal block can be used to split power and deliver it to two different areas of the equipment, and in three-phase applications, the extra position could be used for connecting control signals or other extra circuit needs.

Terminal Block

The terminal block is where the wires are joined together to make electrical connections. The blocks are designed to fit where space is limited, such as inside a computer tower.

Examples of Terminal Blocks

| 3-Wire | 5-Wire | 6-Wire |

|---|---|---|

P/N: 82010010 |

P/N: 82010071 |

P/N: 82010200 |

The different parts of the terminal are the insert, screw, and wire protector.

- The insert is the place in the block where the wire is placed. It is located underneath each “chimney”.

The insert is made out of plated brass. - The screws are located in each chimney. The screws are steel, plated with a zinc and chrome finish. When the screws are tightened down on the wires, the electrical connections are enhanced by the

wire protectors. - The wire protectors are located inside of the insert underneath each screw. These wire protectors are made of stainless spring steel.

The body of the terminal block is molded out of a Polyamide 6. The blocks are able to withstand a continuous working temperature of 100°C (212°F) with a short-time temperature of 160°C (320°F).

The wire connection between the power cord and the terminal block is accomplished through the combination of the insert, wire protector, and screw. When clamping fine wires of small conductor sizes with a clamping screw, the wire protector is positioned between the screw and the wire. This prevents the conductor from being damaged.

Accessory Options

The Interpower terminal block line contains these accessory options: marking label and cover.

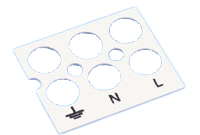

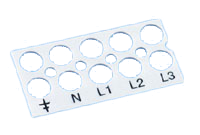

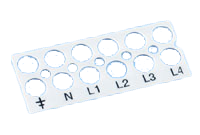

Marking Label

Marking labels allow the terminal blocks to show how they are wired. The markings are based on what size of terminal block is being used. On a 3-wire terminal block, the markings would be a ground sign, N for neutral, and L for line. The same would hold true for a 5-wire label: ground sign, N, and L1, L2, and L3. The six position has a ground sign, N, L1, L2, L3, and L4. Interpower carries labels for all stocked terminal blocks, except for the five position for 10.0mm2 wire.

Examples of Marking Labels

| 3-Wire | 5-Wire | 6-Wire |

|---|---|---|

P/N:82010021 |

P/N: 82010181 |

P/N: 82010211 |

The marking labels are made out of a roughened synthetic material. They come in a standard white color with a thickness of 1mm. There is no temperature rating associated with the marking labels.

Marking labels can be installed either on top of or underneath the terminal block. To allow them to be on top of the terminal block, each pole is provided with two holes allowing the marking labels to be slipped on the “chimney” tops. They are then attached through a fixing hole corresponding to the fixing hole of the connectors. The mounting holes line up when the label is positioned underneath the block. The labels protrude from the terminal blocks along the printed side.

Cover

Terminal block covers serve as protection against accidental contacts. These covers are available for most of the terminal blocks carried by Interpower. There is no cover for the five position for 10.0mm2 wire.

Examples of Covers

| 3-Wire | 5-Wire | 6-Wire |

|---|---|---|

P/N: 82010030 |

P/N: 82010091 |

P/N: 82010220 |

Terminal block covers are made out of Polyamide 6/6 in a gray color. They have a continuous working temperature of 100°C (212°F) with a short-time temperature of 160°C (320°F).

After the terminal block has been attached to the equipment, the covers can be pressed on and are held down by moldings. On the mains supply side, the covers are larger than the terminal blocks. This is so that eventual parallel connections will also be covered.

When marking labels are mounted underneath the terminal block, covers can also be used.

Use and Assembly

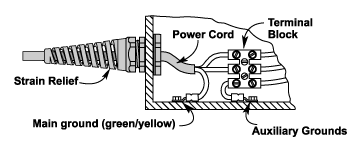

The drawing below illustrates one possible use of a terminal block. The cord enters the product through a strain relief which can be released by using a wrench. It does not have to be removed from the panel in order to release the cable. The cord is attached to a terminal block, which is constructed so that a screwdriver is the only tool required to connect or disconnect it. Solder-type terminal strips are not permissible. Check individual standards for correct use.

One Example of a Terminal Block Connection

Interpower terminal blocks meet both North American and international standards.

Application

Terminal blocks may be used wherever two pieces of electrical wire need to be joined together. These areas are most typically found inside equipment. In a complete assembly, one could see a terminal block being used to splice a power cord together with the internal wiring of equipment.

The strongest advantage of using terminal blocks is that there is no soldering required to make the connections. Terminal blocks also allow for quick and easier repair jobs. These blocks allow for a neater job when finished.

Safety Features

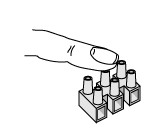

The terminal block must be constructed so that creepage and clearance distances between lines, as well as line and ground, are maintained. The insulation construction must prevent contact with current-carrying surfaces in an attempt to eliminate the possibility of accidental shock. This is accomplished on the terminal blocks by recessing screws and terminals so they are screwdriver accessible only. In this case, screwdriver accessibility means that the standard test finger, which is described in international standards, cannot touch current-carrying surfaces when the terminal block is assembled with wires in place. Check the appropriate appliance standard for selection of the correct terminal block.

Terminal Blocks Illustrating "Touchproof" and "Non‑Touchproof" Terminals

| Touchproof | Non-Touchproof |

|---|---|

|

|

Ratings and Approvals

The ratings on the terminal blocks carried by Interpower vary, depending on the application. Ratings are also based on if they are used internationally or in North America. They have a voltage rating range of 300V-500V. Their amperage ratings are from 10A to 70A. Again, these are dependent on applications and approval country. Approval documents can be reviewed for verification of ratings.

There are different styles of terminal blocks. Interpower has chosen to carry the line of terminal blocks which are recognized worldwide. They are able to have these approvals due to their design. They have a feature called “touchproof”. The terminal blocks are designed in such a way that the screws are impossible to touch with a human hand. The only way to access the screws is with a screwdriver. Terminal blocks that do not have this feature are not recognized in the global market.

For the complete product line, see Terminal Blocks.