More Information on Strain Reliefs/Cable Glands

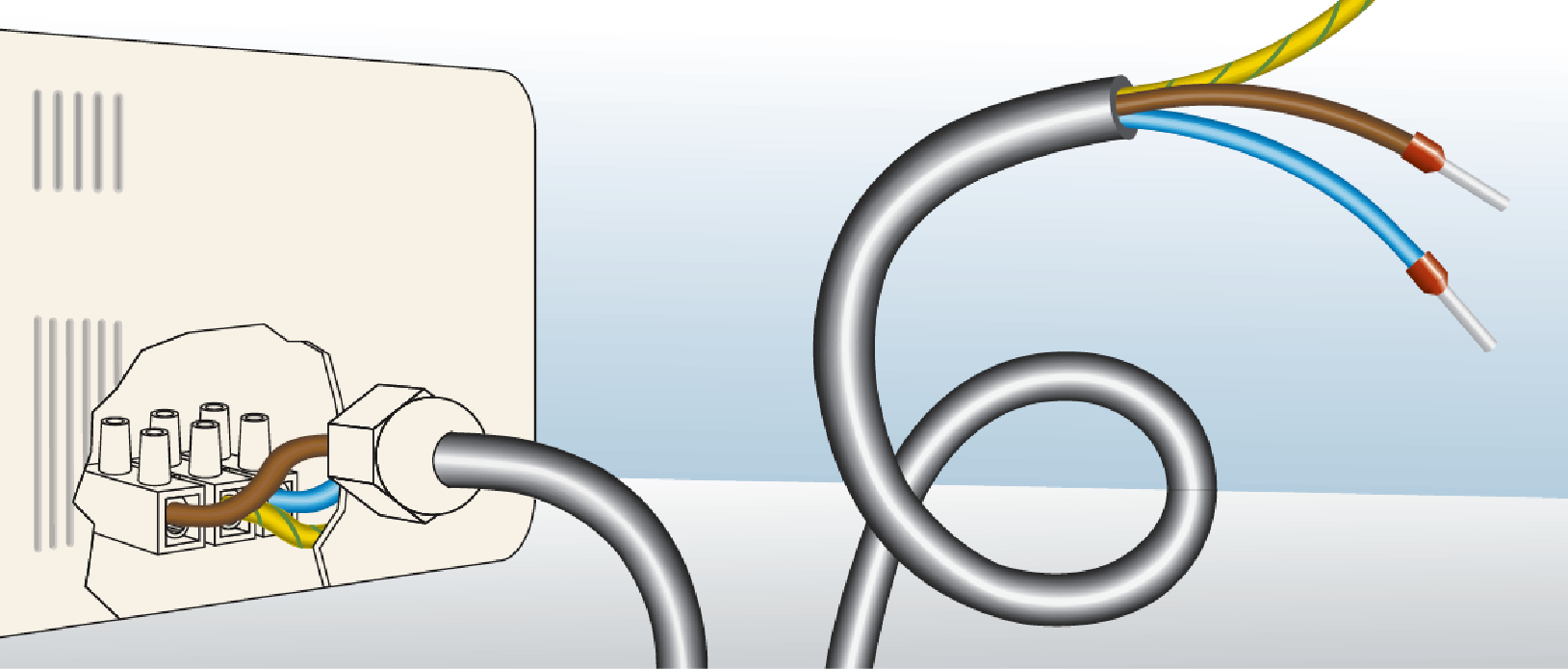

A strain relief or cable gland can provide protection to the wires and cable by securing the cable of a power cord to the panel of the electrical equipment. It helps to protect from stress and damage as it runs through the panel of the equipment. While it does not relieve strain on a cable as it exits the equipment, it does relieve the strain on the electrical connection and circuitry inside the equipment.

The term “strain relief” is commonly used in North America, while “cable gland” is commonly used throughout Europe and the other parts of the world.

Choosing a Strain Relief/Cable Gland

The first step in specifying Interpower strain reliefs is to determine which general type will work best. For applications requiring small to medium-sized cable, several varieties are offered. The aluminum strain reliefs offer the best performance for larger cable sizes. Depending on the application, a strain relief with an integral flex relief may be best. The flex relief protects the cord from stress that is applied perpendicular to the axis of its entry into the equipment. The last step is to select the correct size strain relief for the cord with which it will be used.

Method of Attachment to the Cord

Cord attachment refers to how the strain relief/cable gland and cord are assembled together. Many slide on over the cord and then are tightened down onto the jacket. Some are molded permanently onto the cable. Molded strain reliefs/cable glands bond to the cable in order to hold the cable in place and fill the junction. There is also a mechanical snap-on strain relief/cable gland. These are not liquid-tight and like the molded ones, snap into cutouts with a squared or flat side.

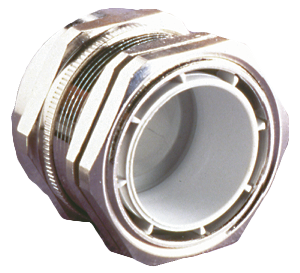

Material of the Strain Relief/Cable Gland

Strain reliefs/cable glands come in a number of different materials, such as nickel-plated brass, nylon, and stainless steel. PVDF (Polyvinylidene fluoride) is a good choice to use on equipment that is around food preparation because it does not retain oils, chemicals, or bacteria that can spoil or poison food. It should be noted that nylon fittings installed in a threaded connection and exposed to elevated temperatures should be retained with a sealing compound to avoid a loose connection when temperatures fluctuate.

Mounting Threads

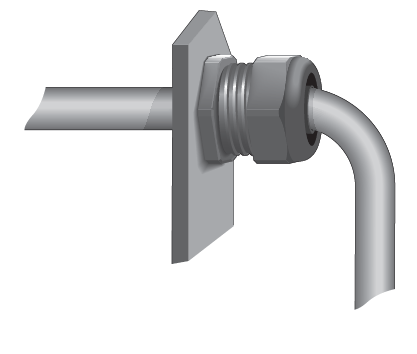

A strain relief/cable gland can be threaded and assembled in different ways. Two examples are the mounting threads can be threaded directly into the panel of the equipment or it can be eased through a clearance hole in the panel and fitted with a locking nut.

Direct Thread into Panel

Clearance Hole with Nut

Methods of Mounting the Strain Relief/Cable Gland to the Framework

The slide-on strain relief/cable gland is threaded and is usually provided with a nut offering two methods of attachment to the panel. One option is to make a threaded hole to fit the size being used and simply thread it into the panel. The other method is to determine the diameter of the cutout hole and use a strain relief/cable gland which is close to the size of the hole. The lock nut will secure it to the panel. Both of these methods can provide a water-tight seal if used with an O-ring.

In contrast, mounting of both the molded versions and the mechanical snap-on versions are done by the use of a cutout mounting hole in the panel and snapping the strain relief/cable gland into place. This makes the assembly time shorter, but does not guarantee a water-tight seal or the cord may not be as secure as the slide-on one.

Specialized Body Styles

Specific body styles are available for many different applications. Typically, strain reliefs/cable glands are available in two general configurations: dome and flex.

Dome Style

Dome style strain reliefs/cable glands are designed to protect the wire entering the equipment.

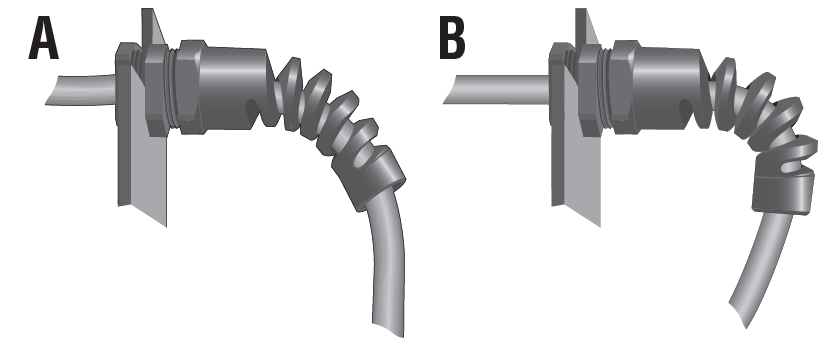

Flex Style

Flex style strain reliefs/cable glands offer flexible bend protection to the cord entering the equipment (A). They are designed to eliminate the possibility of the power cord kinking when the cord is pulled at extreme angles (B).

The spiral shaped spring wraps around the cord and adds strength to the cord where it is most vulnerable to damage.

Cable and Wire Size

Cable size is extremely important when specifying a strain relief/cable gland. The outer diameter of the cable must be known in order to select the appropriate strain relief/cable gland. Each one has a specification of either a specific cable outer diameter size or a range of cable outer diameters it will fit.

Thread Type

Different types of mounting threads that are available include: NPT (National Pipe Thread) which is the American standard; PG (Stahlpanzerrohr-Gewinde; also called Panzergewinde) which is the European standard (German military thread); and metric, which is a general purpose thread used worldwide. The thread system chosen depends on the location the equipment will be used.

If the mounting panel being used has threads, then the strain relief/cable gland should be chosen to match. If the panel has a clearance hole, then the strain relief/cable gland should be chosen according to where the part will be used in the world. If the market is in North America, for example, then choose from the NPT threaded series. If it’s in the European Union, choose metric threads for new equipment and installations. The PG thread is typically for replacement parts for existing installations.

Using a Conduit

Interpower also offers conduit for use with nipples or elbows. This highly flexible corrugated conduit is made of Nylon 6/6 and is flame-retardant and self-extinguishing. Wires or cable are threaded through conduit in situations where the wire and cable need extra protection (from elements or physical damage) or where users may need to add additional wires at a later time.

|

|

| Conduit System (use the filter option) | 85827000 (Conduit) |

|

|

| 85826500 (Nipple) | 85826700 (Elbow) |

Ingress Protection

Dust, dirt, water—all “enemies” of electronic products due to the potential damage they can cause. To help address this issue, the International Electrotechnical Commission (IEC) has created a classification system (IEC 60529) designating degrees of protection regarding enclosures of electrical equipment against the invasion of contaminants, such as dust, dirt, or moisture, plus other foreign bodies (e.g. tools or fingers).

This classification utilizes the letters “IP” (Ingress Protection) followed by two digits. The first digit indicates protection against solid objects intruding into an enclosure. The second digit indicates the degree of protection against the harmful entry of various forms of moisture (e.g. dripping, spraying, submersion, etc.). Within the IP system, the protection level increases as the number designation increases.

Degrees of Protection—First Digit

| First Digit | Description |

|---|---|

| 0 | No special protection |

| 1 | Protection from a large part of the body such as a hand (but no protection from deliberate access); from solid objects greater than 50mm in diameter |

| 2 | Protection against fingers or other objects greater than 12.5mm |

| 3 | Protection from entry by tools, wires, etc., with a diameter or thickness greater than 2.5mm |

| 4 | Protection from entry by solid objects with a diameter or thickness greater than 1.0mm |

| 5 | Protection from the amount of dust that would interfere with the operation of the equipment |

| 6 | Dust-tight; protected from the ingress of dust |

Degrees of Protection—Second Digit

| Second Digit |

Description |

|---|---|

| 0 | No special protection |

| 1 | Protection from vertically dripping water |

| 2 | Protection from vertically dripping water (15° tilted) |

| 3 | Protection from sprayed water |

| 4 | Protection from splashed water |

| 5 | Protection from jetting water |

| 6 | Protection from powerfully jetting water |

| 7 | Protection against temporary immersion |

| 8 | Protection against complete, continuous submersion in water |

| 9 | Protection against high pressure/steam jet cleaning |

Common protection ratings found on Interpower products, such as strain reliefs/cable glands and conduit components, are: IP65, IP68, and IP69K.

- IP65

This rating means it needs to be dust-tight and it needs to be protected against water jets - IP68

This rating means it needs to be dust-tight and be protected against complete immersion in water. - IP69K

This rating is for high-pressure, high-temperature wash-down applications used to sanitize equipment.

If there is only one class of protection, then an “X” is used for one of the digits. For example: IPX4 means it addresses moisture resistance only.

It should also be noted that while this classification system is acceptable for use with most types of electrical equipment, checking with the manufacturer is recommended to determine the exact degrees of protection.

Strain Reliefs/Cable Glands Available at Interpower

There are many different sizes for each type of strain relief/cable gland. To see what is available, see Strain Reliefs/Cable Glands on the Interpower website or click on the link for specific dimensions.

| Liquid Tight Dome Nut | |||

|---|---|---|---|

| Click Here for Liquid Tight Dome Nut Part Numbers | |||

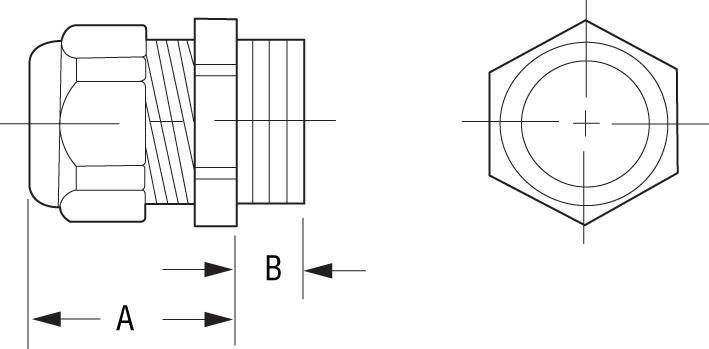

|

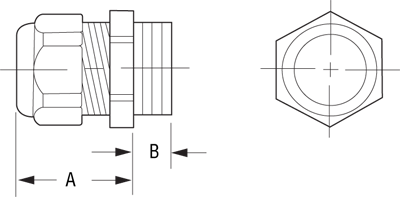

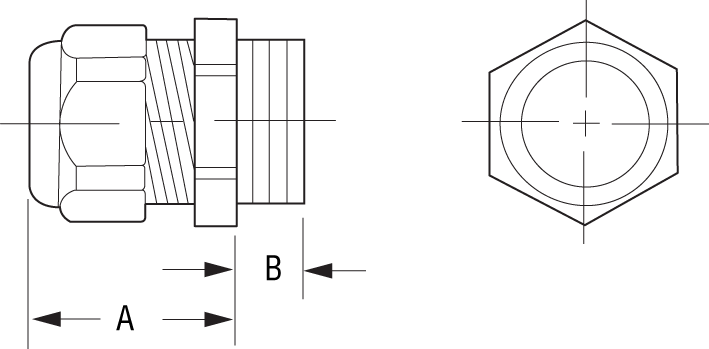

[A=body length; B=thread length] |

||

| Nickel-Plated Brass Dome Nut | |||

|---|---|---|---|

| Click Here for Nickel-Plated Brass Dome Nut Part Numbers | |||

|

[A=body length; B=thread length] |

||

| Nickel-Plated Brass Liquid-Tight Mini Dome Nut | |||

|---|---|---|---|

| Click Here for Nickel-Plated Brass Liquid-Tight Mini Dome Nut | |||

|

[A=body length; B=thread length] |

||

| Liquid Tight Multi-Cable Dome Nut | |||

|---|---|---|---|

| Click Here for Liquid Tight Multi-Cable Dome Nut Part Numbers | |||

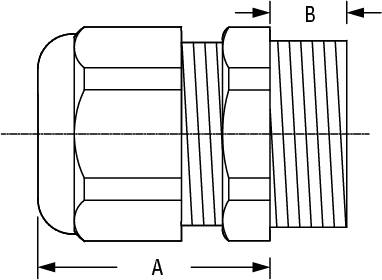

|

[A=diameter of holes] |

||

| EMI/RFI-Shielded Liquid Tight Dome Nut | |||

|---|---|---|---|

| Click Here for EMI-Shielded Liquid-Tight Dome Nut Part Numbers | |||

|

|

||

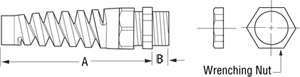

| Liquid Tight Flex Style | |||

|---|---|---|---|

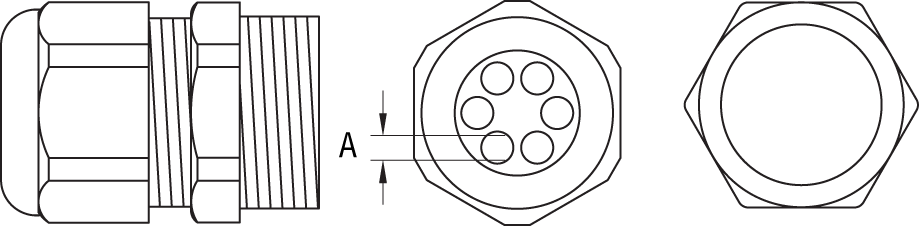

| Click Here for Liquid Tight Flex Style Part Numbers | |||

|

[A=body length; B=thread length] |

||

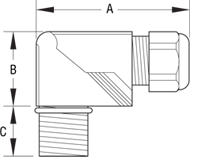

| 90° Snap Elbow Flex Style | |||

|---|---|---|---|

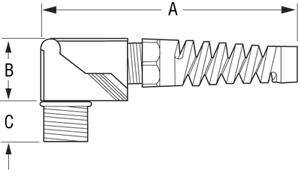

| Click Here for 90° Snap Elbow Flex Style Part Numbers | |||

|

[A=body length; B=height; C=thread length] |

||

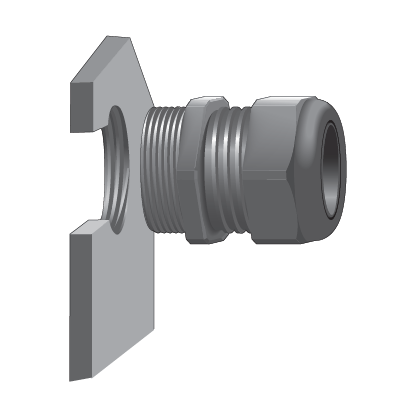

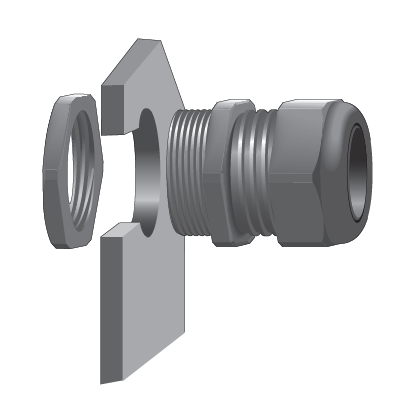

| 90° Snap Elbow Dome Nut | |||

|---|---|---|---|

| Click Here 90° Snap Elbow Dome Nut Part Numbers | |||

|

[A=body length; B=height; C=thread length] |

||

Additional Resources

For more information on strain reliefs/cable glands available through Interpower, see Strain Reliefs/Cable Glands and the Featured Product page.