Socket Strips Can Provide Flexibility in a Product Design

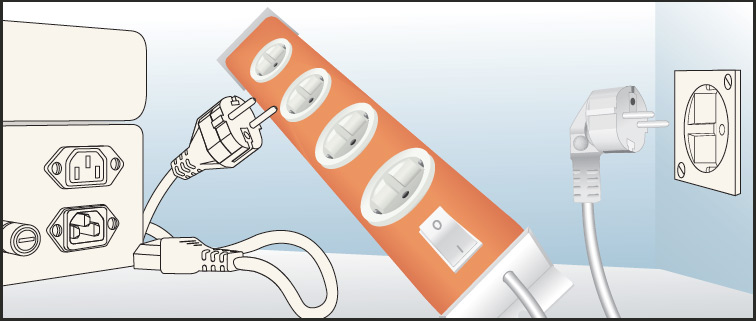

A socket strip can help to give flexibility in a product design with limited socket access by providing multiple sources of power (sockets) in an application.

If a single power source is needed for multiple pieces of equipment, a socket strip may help meet that requirement. A socket strip can distribute electrical power through multiple sockets by being attached to a flexible cable and plugging into a single electrical socket through a country-specific input cord.

Other names for a socket strip include: a RPT (Relocatable Power Tap), a power strip, a power bar, a power distribution unit, and a power board.

Key Components in a Socket Strip

Key components that control the power in a socket strip include: power entry, power control, overcurrent protection, and distribution.

Power Entry

Electrical power enters the socket strip through a country-specific input power cord.

Power Control

The power switch has the ability to power on or off the entire system with one switch.

Overcurrent Protection

The overcurrent protector helps to limit the amount of current in the entire system which helps to protect the equipment from drawing too much current and causing a fire hazard.

Distribution

The distribution of power comes through country-specific sockets, according to where the socket strip will be used.

Overcurrent Protection

“Overcurrent protection is a key element in the socket strip. It can take the form of supplementary circuit protection, such as a CBE (circuit breaker for equipment). The CBE can be in combination with a switch or by itself. The CBE adds overcurrent protection for the socket strip and the equipment connected to the socket strip,” explained Dan Ford, Technical Support Specialist at Interpower.

It is important to know the requirements for the country of export. Many safety agencies have requirements regarding strips that will include circuit protection. For example, in the United Kingdom fusing is required rather than circuit breakers. In Canada, a circuit breaker is required for any strip over two socket positions.

Ratings and Standards on a Socket Strip

When designing a socket strip, another critical factor is determining what the rating needs to be, based on the application and the end use country’s product safety standards. Ratings are listed in voltage and amperage. A key point that Dan emphasized, “It is important to realize that a rating on a socket strip covers the whole socket strip, not just individual components.”

It is also important to note that there is no single standard governing the design of socket strips. Country-specific socket strips typically have approval on the unit given by the product safety agencies in the country in which it will be used. Application and approvals may differ between countries because of various standards.

Part of the focus at Interpower is to make it easy to design, build, and maintain products for global markets. Because there are different standards and requirements around the world, Interpower offer a variety of country-specific socket strips available for the following countries/regions: Australia, Continental Europe, France/Belgium, North America, and the United Kingdom.

Additional Resources

For more information, see Interpower’s product line of country-specific socket strips. See also the socket strips highlighted on the Featured Product page.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.